Heathkit HW-101 Journey

The Pre-Beginning

My HW-101 story begins 45 years before it begins :-)

When I got started in ham radio, I began that journey with a school-mate and friend: sharing Radio Shack morse-learning records, meeting up with local hams, building stuff... and I acquired his used HW-100 as my very-first commercial transceiver in 1976. I used my HW-100 for receive-only; 1977 I got my license and put my HW-100 on-the-air.

In 1979, I packed my HW-100 into a fruit-box and flew to the West Coast for summer work, operating all the while.

I took my HW-100 with me when I went to Queen's University, 1981 - 1986.

My HW-100 was my companion as I moved West, built homes and moved a few times. I bought a Kenwood TS-850, and my HW-100 fell into "backup status"... the VFO was kind of warbly and maybe even jumpy; it languished. When a work-colleague got his ham-license, I gave my HW-100 to him to use...

... and in time I began to miss my erstwhile companion. After all, I'd used my HW-100 for 30 years!

The Beginning

15 years after gifting away my HW-100, I was perusing Craigslist in December 2021, when I noticed an HW-101 for sale. But it was curiously labelled as "...an ideal winter project", and OBO. Intrigued, I contacted the seller, to learn that the HP-23B power-supply had blown up, and the status of the HW-101 was utterly unknown. I took the gamble, and added humour: I offered $101 for this HW-101 with HP-23B and HW-610 speaker :-) I really had not a single clue about what I was buying...

HP-23B Power Supply

Yeah, this baby was in really bad shape :-( It needed a transformer and thermal-breaker; there were arc-pits on the AC-power-plug blades; there were blackened areas inside; there were arc-pits in the actual housing itself! It was almost impossible to determine WHAT EXACTLY had gone wrong, but the AC primary wiring was involved and at least some of the secondaries were involved in the devastating smoke-show.

HP-23B: Taking Stock

At first, I figured I could replace the least amount of components, and get this power-supply running for minimum cost. But as I waited for some parts, and hunted down others, I came to a new place: I opted instead to make this HP-23B the best I could! More than a couple of parts were bought, and I went through a few stages of re-working my re-work to make it the best I could...

HP-23B: Renewal

Months passed - parts were ordered, delayed, arrived, and the process repeated. Ultimately, I wound up with:

- Peter Dahl main transformer. With grain-oriented silicon sheet steel, and rated for Continuous Commercial Service (CCS), this is far superior to Heath's original!

- Up-Rated C1 and C2. 300uF/600V with 15,000hrs life @ 85C, 2.5A ripple-current. Heath specifiedd 7V ripple, and I may see as much as 2A ripple-current (it's not sinusoidal)... with 400V across the cap... nice fit! And again, far superior to the originals.

- With a good low-loss transformer, and larger/better capacitors, I felt the need for inrush-current limiting. Add an Amphenol CL-80. But really, I have to evaluate (and maybe change) this, once I perform real-world testing with the actual load. TBD.

- Transient Suppression: check! Varistor MOVTP20V130 with 130VAC working voltage, 200VAC nominal up-tick to 1mA leakage... another good fit.

- I wanted to treat the HW-101 Volume / Power-Switch kindly. Sure, my Amphenol inrush current limiter will be awesome, but so will... using a solid-state relay! My HW-101 power-switch will now be asked to pass mere milliamps, while the SSR is rated for 10A. The Gordos SSR will only turn on when the voltage waveform is at 0V, again softening any inrush. Kinder and gentler.

- High-Voltage diode strings got replaced with single, much-higher-rated diodes: IXYS DNA30ER2200IY rated 2.2kV 30A!! Whooo-Hooo! Nominal operating is 800V @ 250mA so I have a metric-tonne of headroom :-)

- Even the Low B+ and Bias supplies received 1N4007 diodes and up-rated caps.

- All Heath's 100k bleeder resistors were originally carbon-composition, rated 2W but called-upon to dissipate 1.6W ... All got uprated to 3W 1% metal film for long-term happiness.

- eBay provided a new-in-package thermal breaker, complete with the funky red push-stick "reset" :-) This Littelfuse is rated "do not trip" 3.9A and "must trip" 6.0A. For this radio, rated to consume ~300W AC power at full-roar, a 4A slow-blow seems OK (Heath originally used a 3A slo-blo in the HP-23, but later changed that to 4A slo-blo to avoid nuisance-tripping).

- I disliked Heath's original flat, 3-rib power-cord, so I bought a round, light-grey one that I preferred. New Heyco strain-relief too, to fit the round cord. Pro-Tip: I don't have the Heyco pincer-style installer-tool, and I hate the way pliers chew the strain-relief... Install the strain-relief onto the cord, then clamp it snugly in a (soft-jaw!!) vice for 30min. Quickly un-vice, and insert into chassis-hole for simple fingers-only installation. Things will relax a bit, to expand the strain-relief and hold it.

- I don't know here Heath bought their hardware, but the plating all becomes dingy and dull over the years. I opted for all stainless machine-screws, lockwashers and nuts, in both 8-32 and 6-32 flavours, Philips pan-head. Typically the lockwashers were anointed with nickel-anti-seize to prevent any (disimilar-metal-) corrosion and oxidation, while maintaining conductivity through the fastened joint for a very long time. Nuts and machine-threads received Loctite Purple (weak) threadlocker, to help keep everything together.

- I had abundant rotor-cable, and I could have duplicated Heath's wiring-colour-scheme, but instead I chose to use a bunch of white wires :-O It's nowhere near as bad as it sounds - the wires are hand-laced into functional bundles, and I used 3kV silicone-insulated 22ga/18ga/16ga.

HP-23B: Testing

No-Load Voltages:

775VDC Final Plate Voltage

324VDC Screen and other Plate Supply

-130VDC Bias Supply

12.8VAC Filaments

Satisfied that I now had a rock-solid, properly-operating Super-Power-Supply, I could turn my attention to the HW-101.

Mug Shots - The Photos

Click for larger...

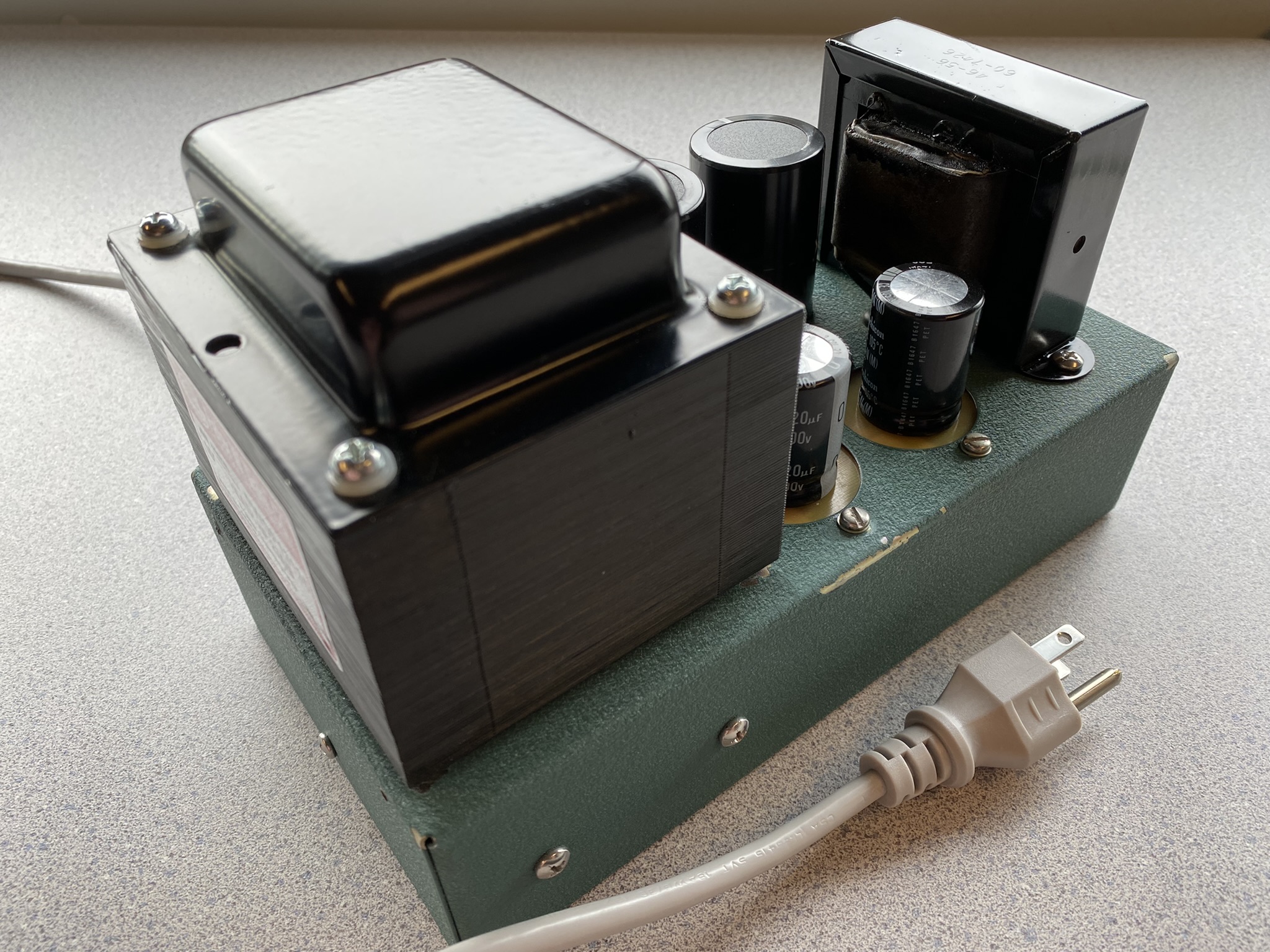

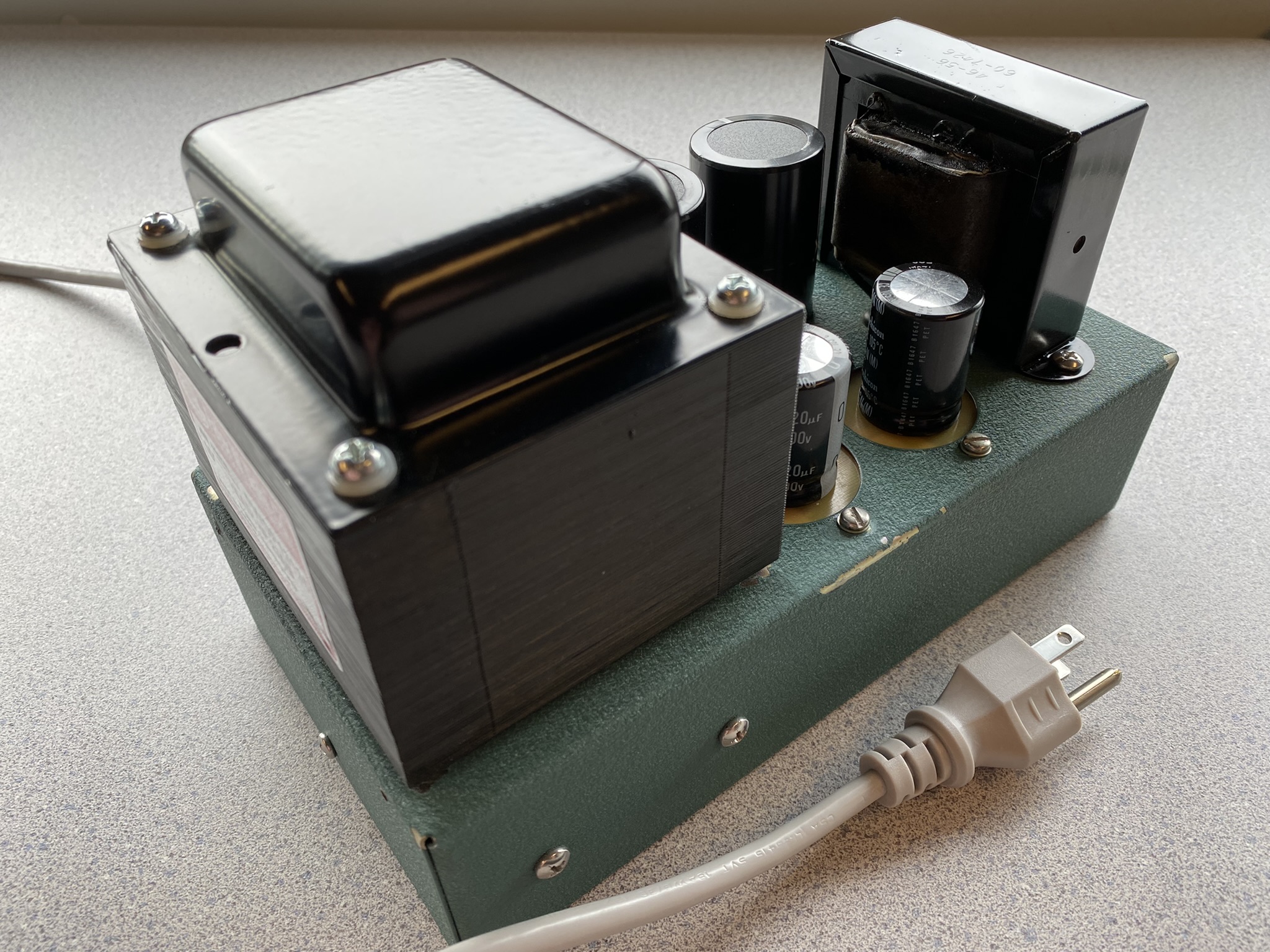

| Some character-lines, but aging with dignity. The steel chassis shows no rust, despite some paint-chips. Generally, this HP-23B is clean. The chassis shows signs of having had a cover installed at one point, but I am using it cover-less in the SB-600 speaker. Which, by the way, is one reason I chose a grey power-cord: to co-ordinate with the putty-grey of the SB-600. Fashionista :-) |

| With this view of the HP-23B, you begin to see the added mounting-scews for the Gordos Solid-State Relay. |

| Mandatory: a new transformer (because the original/burned one did not arrive with the supply). I opted for a Peter Dahl custom transformer, with Continuous Commercial Service rating (in contrast to Heath's ICAS (Intermittent Commercial and Amateur Service) rating). Perhaps the star of the entire rebuild! |

| Full interior view. See, all my white wires aren't too horrible, are they?

The transformer-leads are almost half of the wiring anyway, and they don't match the original Heath colours/stripes.

Black Transformer leads = primary windings. Yup, this transformer has two windings, for 120 or 240 VAC operation. I've hardwired it for 120VAC because that's the rating of the SSR, my MOV matches, the plug is a standard 120V NEMA-15P, and my usage indicates that this will only ever see 120. I am committed (or should be :-) :-) ). Red transformer leads = High B+ Blue Transformer leads = Low B+ and Neg Bias Green Transformer leads = 12.6VAC Filament (with unused center-tap) |

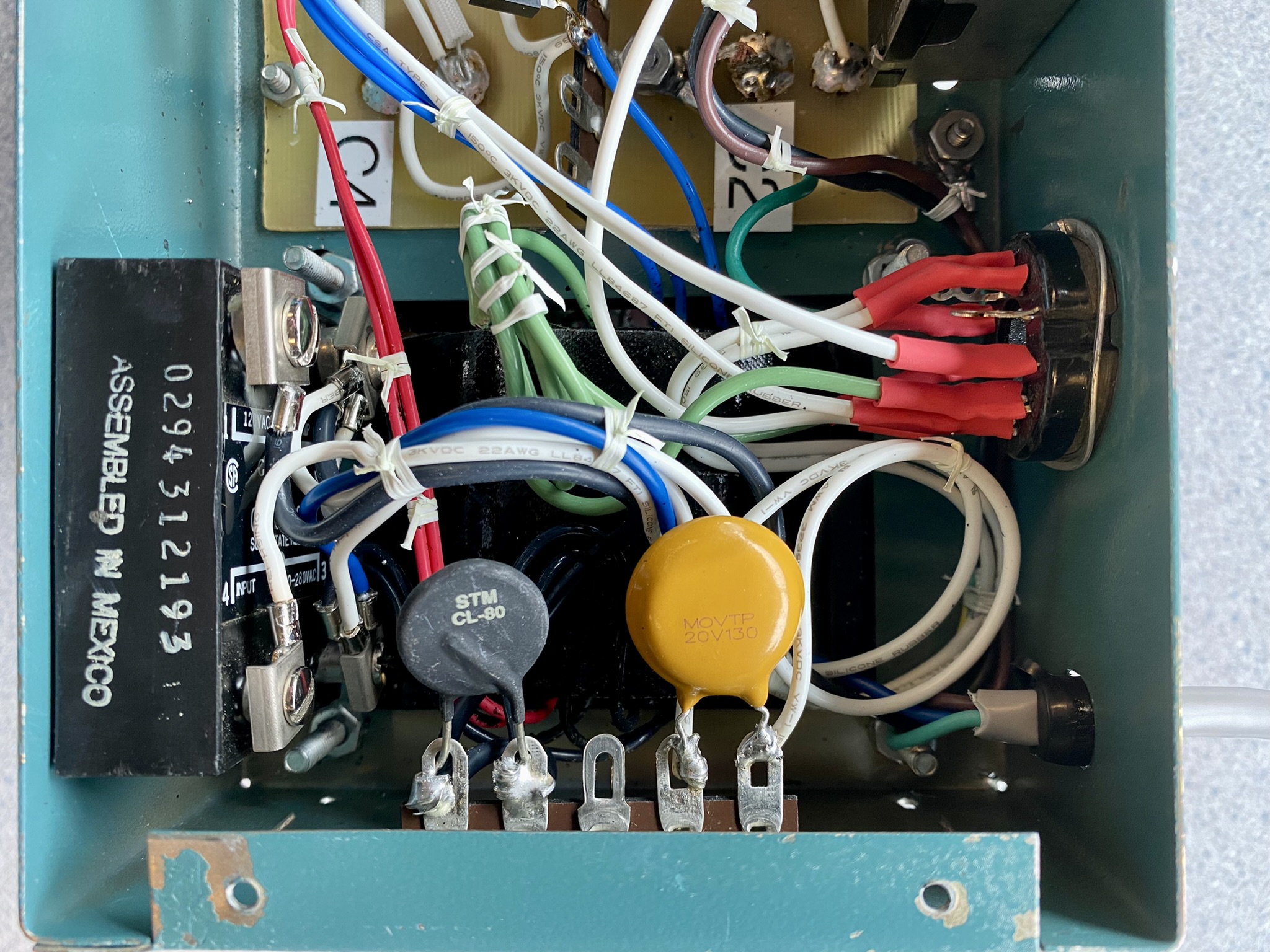

| Partial interior view. Here you can see the (yellow-disc) MOV I added for transient suppression. This is located upstream of any switching, so it's active across the AC power whenever the HP-23B is plugged-in.

The negative-temperature-coefficient inrush-current limiter is the black disc - it's downstream of the AC power switching, in series with the transformer primary.

And the black rectangular Solid-State Relay graces the side wall, where it neatly fits between the chassis top and bottom, as well as neatly between the transformer mounting bolts.

I added the terminal-strip for this AC power wiring, relocating all these AC power connections away from the HV / Low-B+ rectifiers and filtering. |

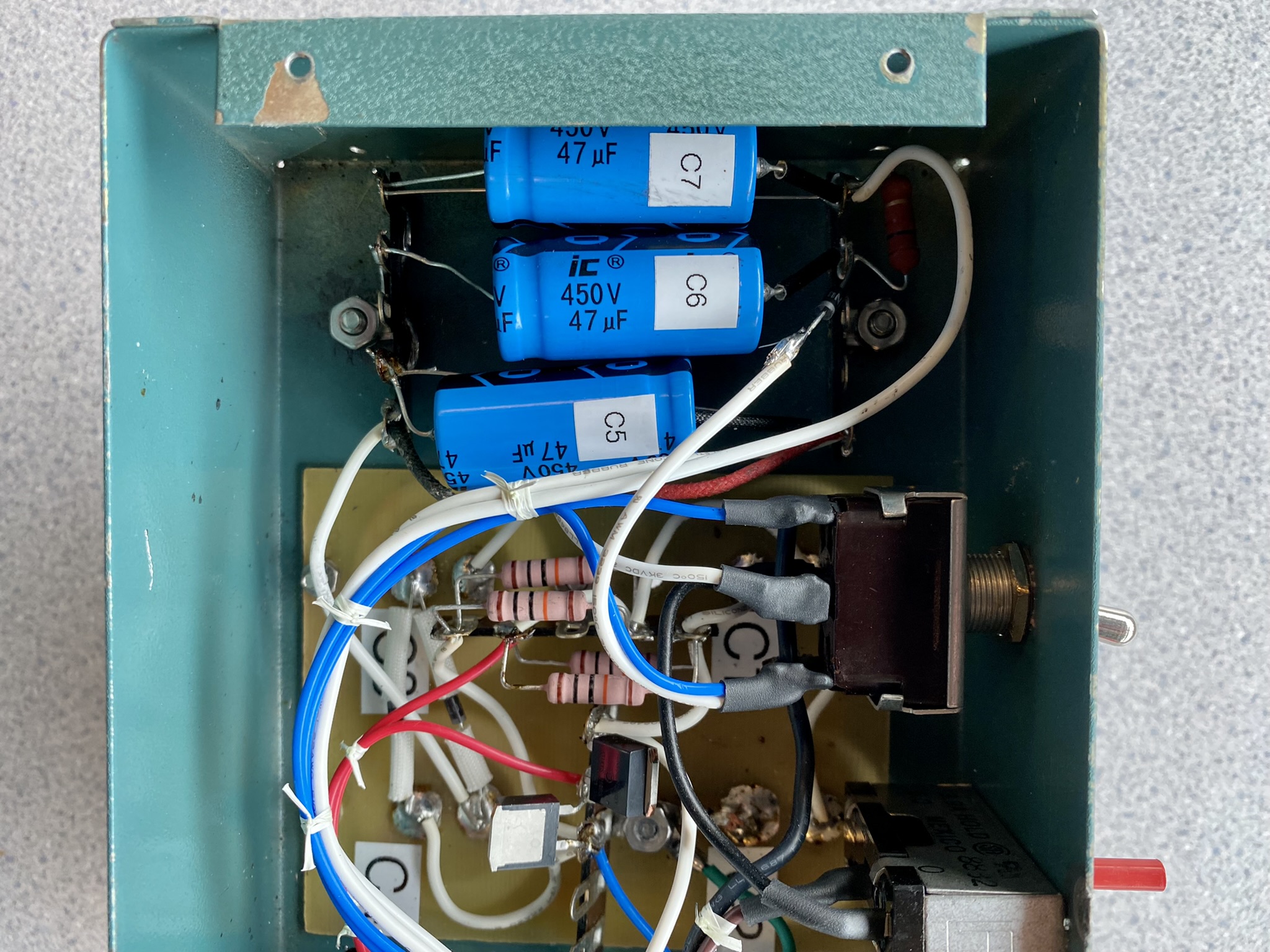

| This partial interior view shows my interpretation of the HV rectification with fewer diodes. Also, both the Low B+ and Bias received the same capacitors, for simplicity of ordering and tons of extra margin.

I added another terminal strip to more-securely mount the bleeder resistors (hidden beneath the capacitors) and filter capacitors themselves.

All capacitors are labelled, so I have a chance of figuring out what I did, in years-to-come. Or, maybe a future-owner will thank me :-) |

|

| This HP-23B (serial 435) starts up quietly, with no magnetostriction "bwang", and it runs without hum or buzz. |

| And there we have it... HOLY COW - CONTINUOUS COMMERCIAL SERVICE!

|

Power Supply Cable

I had the original Heath cable which came with everything I bought, but the cable was semi-rigid now, featuring the short-inducing metal backshells. This cable embodies "Heath Original".

I subsequently bought a Heath "cable kit" from eBay, which had two new 11-pin connectors, rubber backshells, and some Wireman 8-conductor rotor cable. I built this, then paused... I decided I was uncomfortable with the wire-gauge / ampacity of the included Wireman rotor-cable, also of unknown voltage-rating. And the vendor did say it reflected Heath specifications, so my discomfort then transferred also to the Heath Original cable. :-O

I decided to built my own cable, using wires that were proper and completely appropriate for each task. I selected:

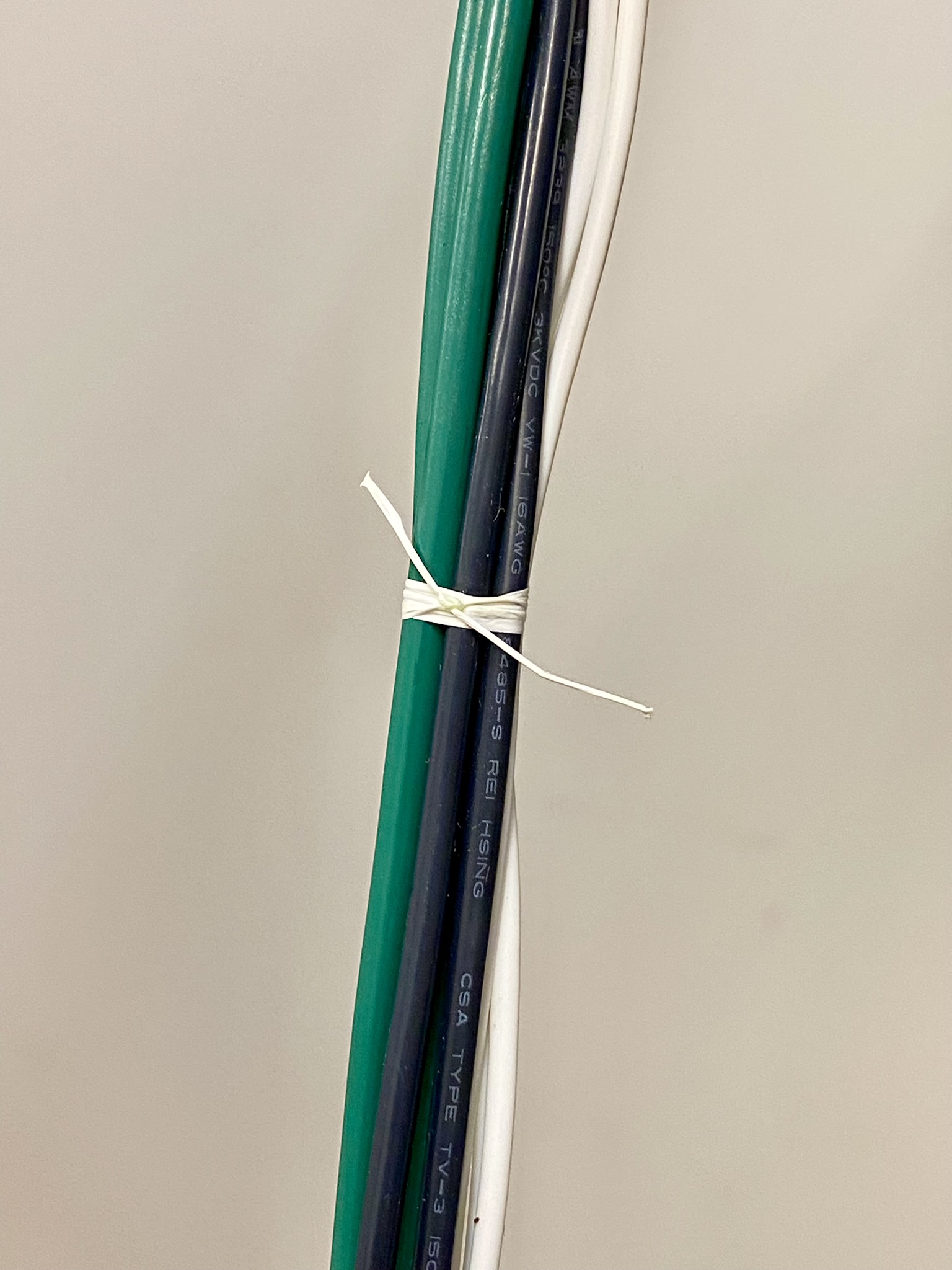

- 2x 14AWG 41-strand PVC-jacketed green wires for the filaments (5.5A). Even 16AWG was going to lose me 1/2-volt, and Heath-original 18AWG might almost drop about 1V on the way to the radio (and back)! No way I wanted that. Insulation rated 600V, which will surely be fine for 12.6v :-) Ampacity and voltage rating - superior to original and that feels great!

- 2x 16AWG 26-strand silicone-jacketed black wires for the AC power switch. I don't need this with my solid-state relay, but in case I later use this cable with a stock HP-23 I wanted to make sure it could handle the current with minimal voltage-drop. And for sure this cable is good for 120VAC... because it's rated to 3kV!! Ampacity and voltage rating - superior to original and that feels great!

- 3x 22AWG 17-strand white wires for the HV (250mA), the 300V (150mA), and the -130 negative bias (20mA). This is the only place I agreed with Heath (wire gauge), but I uprated using high-strand and silicone-jacket rated 3kV.!

- 1x 14AWG 41-strand PVC-jacketed green wire for the (shared, common) Ground connection. Because no-one loves mutual IR drops coupling between supplies :-O

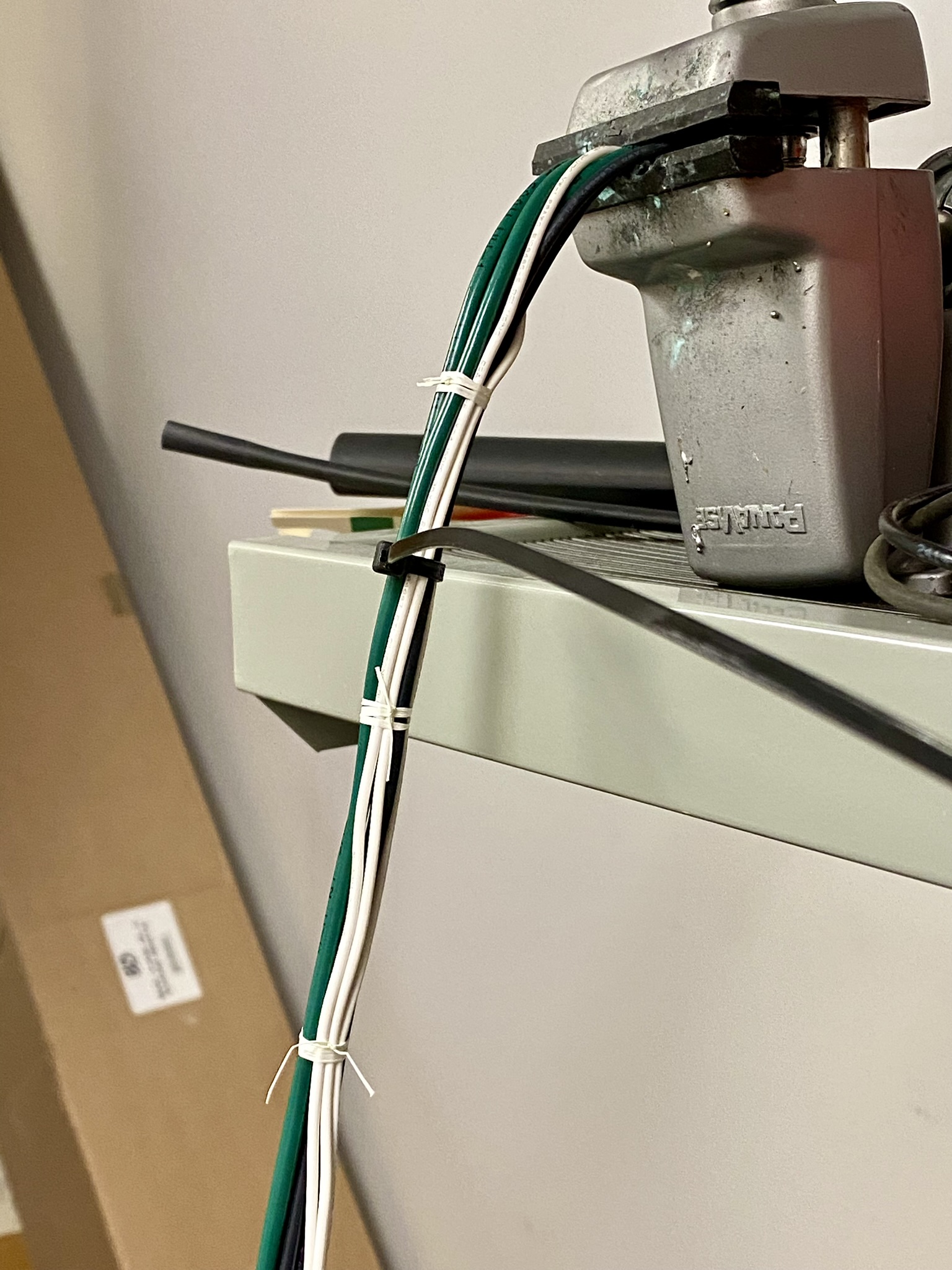

Both the high-strand counts and the silicone jackets were intended to allow flexibility for the finished cable. I find it more flexible than either original Heath, or the eBay+Wireman products. My bundle is 3/8" diameter - about the same size as Heath's but thicker than eBay+Wireman. To retain the flexibility, I used (non-running) lacing... lots of individual pieces and knots.

|

| The custom power cable began with cutting 6-foot lengths of each wire, securing them in a dangling position, then lacing. Lacing is gentle on the wires, won't cut me like tie-wraps, and will easily allow sleeving to slip over |

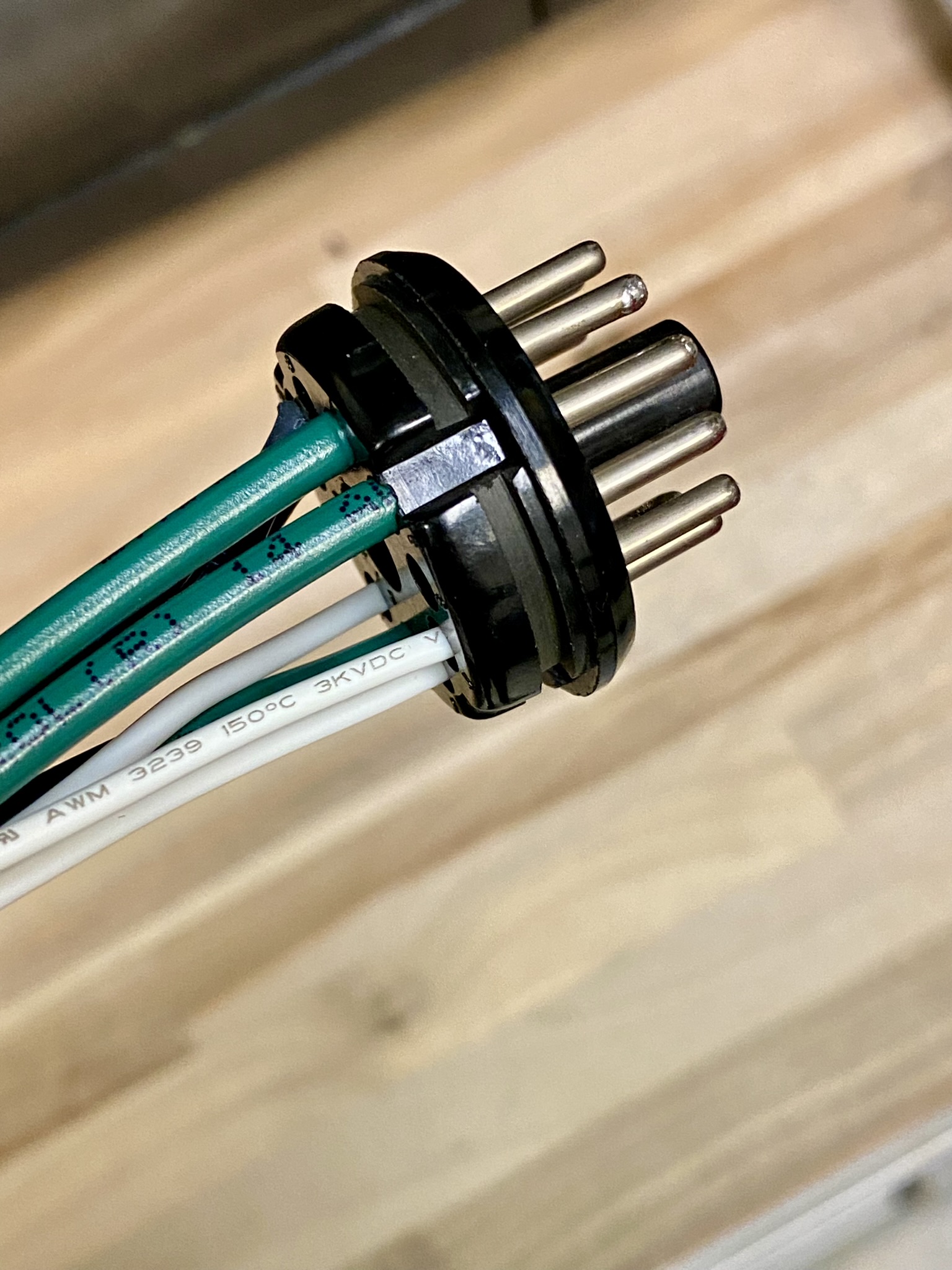

| I began wiring the cable from the plug-end, because it was a bit more-finicky: the 14-ga wire required 10 strands to be cut, in order to reduce the diameter and allow the remaining 31-strands to fit into the pins. The 16-ga AC-switch wires just barely fit into the pin center-holes without any strand-trimming.

|

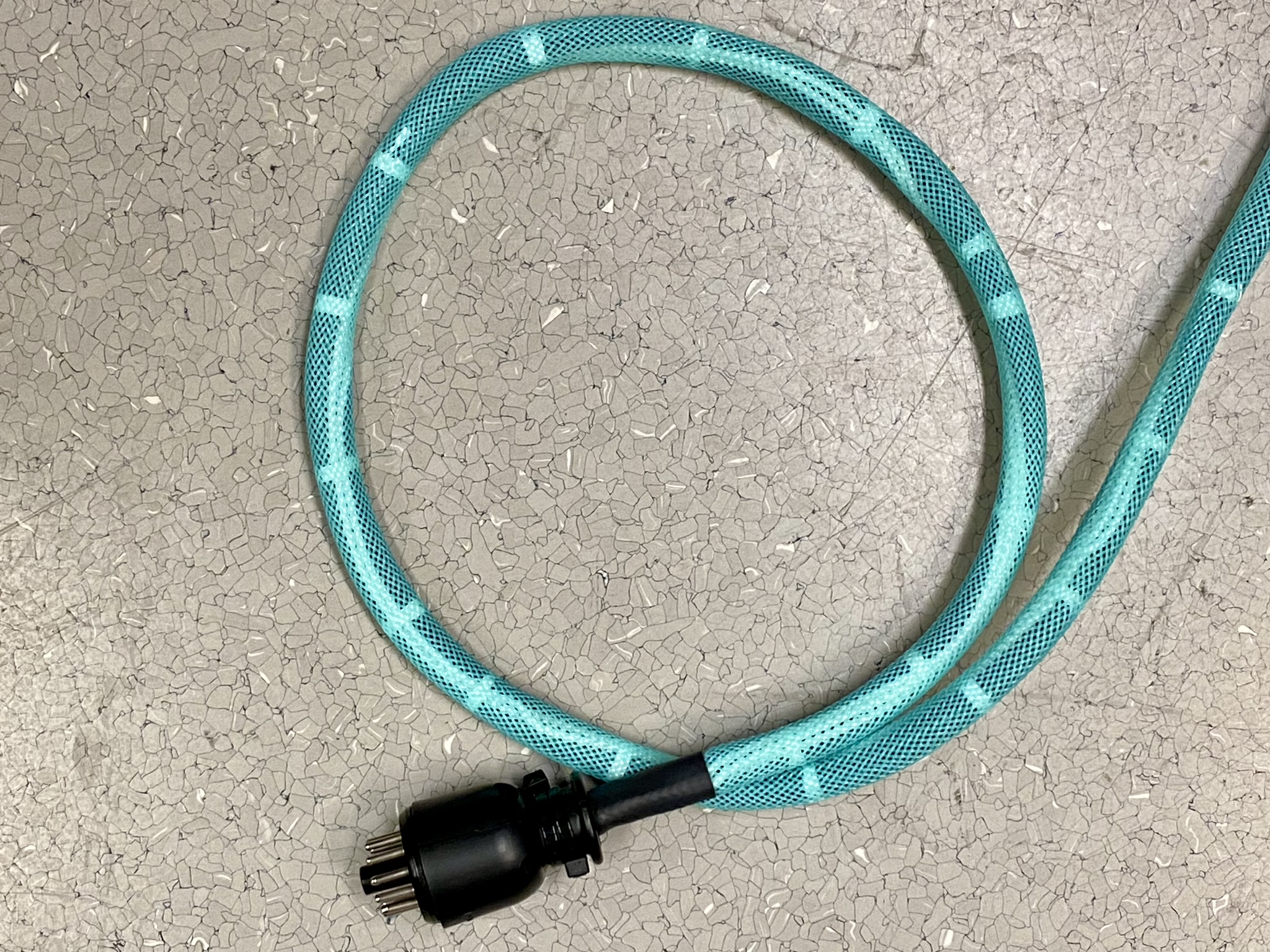

| Braided sleeving slid over wire-bundle, glue-heatshrink applied, and rubber backshell installed. I had to drill out the backshell's internal ribs to accomodate the wire-bundle, and still a couple of tie-wraps help snug the backshell. I've hit the limit for the wire-bundle and this rubber backshell.

I opted for Aqua coloured sleeving, because it was about the closest to the HW-101 light green panel colour - always fashionable :-)

The Techflex Flexo PET braided sleeving is FMVSS 302 Approved, UL-94V0 flammability-rated, resists lots of chemicals and UV, can operate up to 125degC, and is UL/CSA rated. Not just another pretty face.

|

| The Whole Enchilada!

That RG-174/U sprouting out the side of the connector backshell is the Relay-Closure, intended to trigger an Amplifier into TX. While I do have an amplifier, I don't really envision using it with the HW-101, but I may change my mind. If I do change my mind, I only have to install an RCA connector onto the RG-174 and I'm in business.

The cable was tested in the usual way: jumper AC-switch pins 9 and 10 to turn on the HP-23B, then measure voltage on pins. And it did test good :-)

|

HW-101: Taking Stock

I had to open it up, whereupon I found I had replacement silicone belts, bags of replacement parts, and the elusive CW filter!!! Yay!